Binding

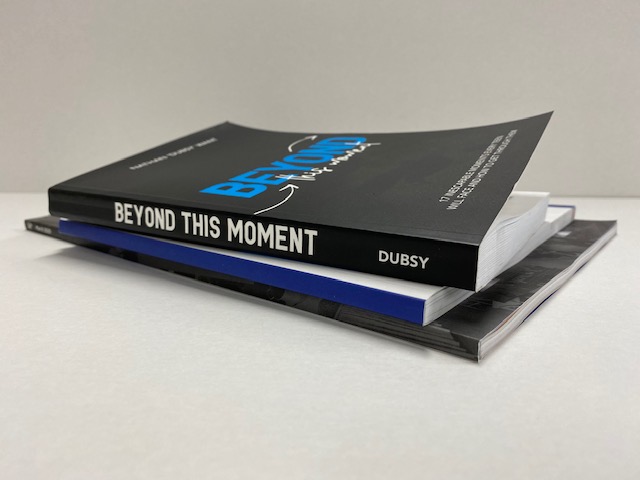

PUR Binding / Perfect Binding

PUR Binding refers to a softcover book binding method that makes use of Polyurethane Reactive (PUR) adhesive. PUR Binding is a form of perfect binding, where the pages and cover are glued together at the spine and the other three sides of the book are trimmed as needed to give them clean “perfect” edges. It is very popular with long run catalogue publishers who want their high page count products to have extended shelf life and so is ideally suited to documents with a high page count.

Polyurethane Reactive (PUR) is the most durable book binding glue available. It is far superior to Ethylene Vinyl Acetate (EVA) or any other adhesives used in traditional perfect binding.

Bottom Line: If quality and durability are important to you, always select PUR binding when you have the choice.

Perfect Binding is the same process as PUR binding but EVA (Ethylene Vinyl Acetate) hot melt glues are used.

Important Tips: The cover must be 4mm bigger than the head and the foot of the untrimmed folded text to allow a glue trap.

PUR finished products cannot be opened or used for 12 hours after binding process.

MAIN BENEFITS

PUR has superior flexibility, which prevents the spine from cracking when the book is opened wide or pressed down flat.

PUR can adhere to a wide variety of substrates, including ink, varnish, recycled paper, mylar, and UV-coated or aqueous-coated stock.

Compared to EVA adhesive, PUR offers 40% to 60% better resistance to page pull-out. In fact, it is nearly impossible to pull a page out of a book bound with PUR adhesive.

PUR’s performance and structural integrity is unaffected by extreme cold or hot environments (-40º to 200º Fahrenheit).

Because PUR is so strong and pliable, less adhesive is needed to firmly bind the cover and pages. Less glue means less distortion of the spine’s shape, resulting in a crisp, square appearance…even on thinner books.

SPECIFICATIONS

Sizes offered by Terrell Print Finishers:

BOOK BLOCK / SECTIONS: Minimum: 145mm x 105mm

Maximum: 320mm x 320mm

FINISHED TRIMMED SIZE: Minimum: 100mm x 75mm

Maximum: 315mm x 315mm

Minimum spine: 1mm (text)

Maximum spine: 65mm

Minimum cover size: 135mm x 225mm

Maximum cover size: 320mm x 660mm

For options for fold flaps on covers please enquire.

Burst Binding

Burst Binding is a widely used soft cover bookbinding method. With this method, the pages and cover are glued together at the spine with a strong yet flexible thermal glue. The other three sides of the book are then trimmed as needed to give them clean “perfect” edges.

Burst Binding is a type of binding in which the spine is slotted or specially perforated during the folding operation. An adhesive is then pushed up between the perforations during the binding process, the drawn cover is added on during this process.

Burst bound books have a square, printable spine and the cover is usually made from paper or card stock that is heavier than the interior pages. If desired, the cover can be clear-coated to provide durability and improve appearance.

Important Tips: The cover must be 4mm bigger than the head and the foot of the untrimmed folded text to allow a glue trap.

MAIN BENEFITS

It is less expensive than hardcover binding methods.

This method will accommodate a high page count.

It can be used for very short production runs.

Books can be made with a heavier weight cover for durability and longevity.

This method forms a flat spinal edge which can be printed upon.

The finished shape allows books to stack well for storage and display.

SPECIFICATIONS

Sizes offered by Terrell Print Finishers:

Minimum trimmed: 145mm x 105mm

Maximum trimmed: 410mm x 235mm

Minimum untrimmed: 155mm x 110mm

Maximum untrimmed: 420mm x 245mm

Minimum spine: 2mm (text)

Maximum spine: 50mm

Minimum cover size: 135mm x 225mm

Maximum cover size: 420mm x 615mm

Saddle Stitching / Loop Stitching

Saddle Stitching is a relatively simple method which joins the folded pages and cover with at least two wire staples placed through the crease of the book’s spine. Though simple, the result is a very professional looking document. Of all the softcover book binding methods we offer, Saddle Stitching is the most popular. We use this method for a variety of book types including catalogues, manuals, booklets, programs, multi-page brochures, newsletters, wall calendars and mailers.

Loop Stitching is the same method as Saddle Stitching except you change over the stapling heads to produce looped staples so the finished product can then be put in a ringed binder.

Important Tips:

- It is recommended that the cover stock’s grain runs head to foot to minimise spine cracking.

- All sections should have a common front lap for section pick up for the stitcher. The minimum requirement is 7mm.

- Because a Saddle Stitched book is created from folded sheets, the page count must be in multiples of four.

MAIN BENEFITS

The turnaround time is generally quite fast

Can be printed in full colour, with plain black ink or in any ink combination.

It can be used for very short production runs.

Books can be made with a heavier weight cover or as “Self Cover” books. Self-Cover means the cover is the same weight of paper as the interior pages.

It allows for books to be made in a wide range of sizes.

Books can be hole punched along the spine for insertion into a ring binder.

Relatively easy to design and can accommodate artwork or images that span two adjacent pages (crossover images).

Adds minimal bulk or weight to the printing, so it is especially good for pieces that will be mailed.

SPECIFICATIONS

Maximum finish size: 475mm x 300mm

Minimum finish size: 105mm x 75mm

Maximum untrimmed folded text size: 480mm x 320mm

Minimum untrimmed folded text size: 145mm x 100mm

Maximum finished product thickness: 5.5mm (size limited)

6 Work stations in total

2 up manufacture must have 10mm gutter trim

TPF can process two or three loop staples at one time

Wire-O Binding

Wire-O Binding, also known as Twin Loop, Double-Loop, Double-O, or simply Wire Binding, is an attractive method for joining the pages and cover of a bound document. The Wire-O binding method utilises pre-formed pairs of wire loops that run along a C-shaped unit. These wire loops are inserted through holes that have been punched through the book’s cover and pages. The loops are then crimped closer together until they form a perfect circle, thus securing the cover and pages as an assembly, yet allowing them to open freely. Our standard default colour is black or white, but we do carry a few other colours. Wire binding offers a variety of cover options, the most common are:

- Standard Binding – this is the usual binding you generally see.

- Full Canadian – the Full Canadian method has the wire fully concealed by using a 6pp or 8pp cover. The cover leaf is folded back on itself to be bound into the wire, resulting in a book with a square spine and uninterrupted covers.

- Half Canadian – This method has the wire partially concealed behind a square spine. The cover is normally a 4pp cover, with the spine printed on – which mimics perfect binding, but has the advantage of the book being able to be opened completely flat without damaging the spine. The wire is exposed through the rear cover only, leaving the front cover clear to display the printed image.

- Tent Card – a free standing triangular cover which allows the finished item to be used as a free standing desk stand.

MAIN BENEFITS

Books open 360 degrees (cover to cover) which allows them to fold flat and lie flat for easier reference.

The dual wire coils add a very distinctive appearance to bound documents.

It is a readily available binding method.

Can be used for very short production runs

This binding style works well with index tabs.

This binding style works well with index tabs.

SPECIFICATIONS

Maximum finish size: 550mm x 550mm

Minimum finish size: 50mm x 75mm

Maximum finished product thickness: 22mm

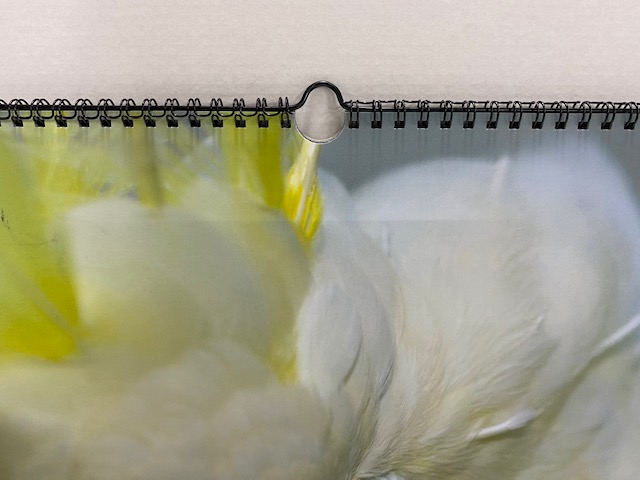

Wire Calendar Binding

Wire Calendar Binding is very similar to wire-o binding except there is a half circle thumb hole cut out in the middle of the punch holes so a hanger can then be inserted. Wire Calendar binding is mostly used for calendars, wall charts, emergency charts and any other product that needs to be hung on a hook.

MAIN BENEFITS

Calendars open 360 degrees over themselves which allows them to fold flat and hang nicely on the wall.

The wire colour can be matched to the hanger colour.

Can be used for very short production runs

It is a readily available binding method.

SPECIFICATIONS

Maximum finish size: 500mm x 550mm

Minimum finish size: 80mm x 75mm

Maximum finished product thickness: 6mm

- Hangers come in black or white colour only.

Plastic Spiral / Coil Binding

Spiral and Coil Binding are interchangeable terms for the same book binding method. This popular method joins the pages and cover of a book using a durable plastic coil. The coil is inserted and twisted through small holes punched along the spinal edge of the book’s cover and pages.

One of the primary benefits of a spiral bound book is that the pages can be opened a full 360 degrees (cover to cover). This allows an open book to fold back upon itself and yet still remain flat, so it stays open for easy reference and yet takes up minimal room on a desk or table.

Spiral binding is an excellent choice for reports, sales presentations, proposals, directories, cookbooks, instruction manuals and maintenance guides.

MAIN BENEFITS

Books open 360 degrees (cover to cover) which allows them to fold flat and lie flat for easier reference.

The turn-around time is generally quite fast.

Can be used for very short production runs.

Coils come in a variety of diameters to accommodate books of varying thicknesses.

It allows for books to be made in a wide range of sizes – small like a pocket guide or large format books.

Plastic coils resist distortion and are available in assorted colours to complement the book's cover.

SPECIFICATIONS

Maximum finish size: 550mm x 550mm

Minimum finish size: 50mm x 75mm

Maximum finished product thickness: 33mm

PUR BINDING

BURST BINDING

SADDLE STITCHING

WIRE-O BINDING

PLASTIC SPIRAL BINDING